-----

What is the required thickness of Nickel Plating

Q. Can anyone tell me the correct amounts of copper and nickel that is required for standard nickel plating? I have been informed it should be 20 microns of copper and 8 microns of nickel. I can't find any standards or specifications regarding this matter. Your help in this matter would be very grateful.

Carl Newman- Northampton, UK

2002

A. Hi, Carl.

It depends on what the substrate of the product is (steel, brass, zinc die-casting, etc.), and what the exposure conditions are (indoor, outdoor, severe, marine, etc.) Depending on which specs you want to follow, there will be different "service conditions" that suggest or require require different thicknesses of nickel. But it is not certain that ANY copper is required, as it probably doesn't contribute to corrosion resistance. And duplex nickel (semi-bright followed by bright) is best for exterior use. One excellent reference is the MFSA's "Quality Metal Finishing Guide to Copper-Nickel-Chrome Plating". See www.namf.org for ordering info. Good luck.

Good luck.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

I AM DESIGNING A FINNED TUBE HEAT EXCHANGER FOR GENERATOR WORKING AT COASTAL AREA NEAR ARABIAN SEA.COPPER FINS(.15MM THICK) WITHSTAND

1.5 YEARS AT THAT CLIMATE.I WANT TO INCREASE THE LIFE OF COPPER FINS UP TO 3.5 YEARS. I AM ALLOWED TO COAT FINS WITH NICKEL.

I HAVE NO KNOWLEDGE WHAT THICKNESS OF COATING I WILL USE FOR EFFECTIVE HEAT TRANSFER.

STUDENT ON INTERNSHIP - LAHORE, PAKISTAN

2007

Thickness of nickel plating over brass for offshore application?

Q. We are going to use nickel plated brass for cable glands in a harsh environment for offshore application. Supplier is offering 4 micron of nickel plate over brass. The question is how to be assured that thickness is enough for the offshore application? I would like to know which type of weathering test and with what acceptance criteria is useful in this matter?

Afshin FarshidfarOffshore electrical designer - Tehran, Iran

September 18, 2013

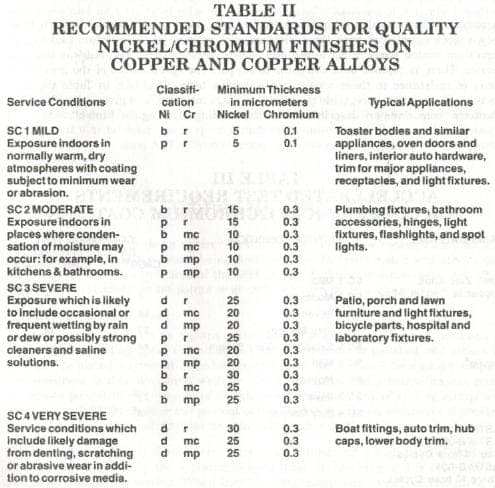

A. Hi Afshin. Unfortunately, I don't think this will be remotely satisfactory. Please see attached chart from MFSA Quality Metal Finishing Guide for Copper-Nickel-Chromium and Nickel-Chromium Coatings (Vol. V, No. 1).

I'd strongly consider stainless steel cable glands, as properly nickel-chrome plated brass glands might be very expensive. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread