-----

Brightener for acid copper plating

Q. Amateur Hobby plater also looking for a generic brightener/hardener for simple copper plating. I have found some references to sugars, sulfurs and molasses. However little real world results reported. Could it be blackstrap molasses that contains sulfur compounds works because of the sulfur? Or sugar?

Don't need or want to pay for professional expensive products, nor need perfect results. Just want something a little shinier and harder than my current soft dull deposits. Looking for dosing for molasses. Thank you and this is a great site. (I also do some silver plating using non-cyanide formula and have good brightener for that.)

- Wisconsin, usa

December 13, 2017

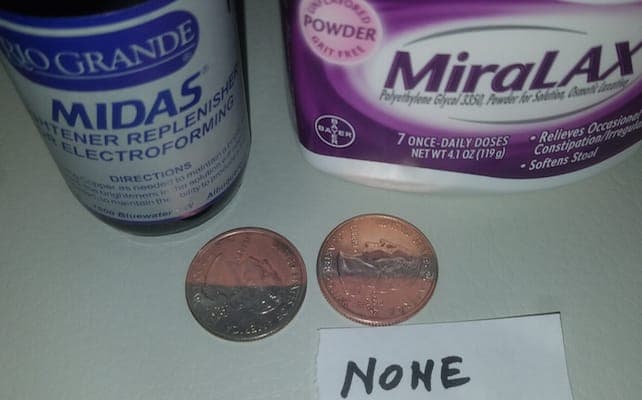

A. Hobby beginner electroplater here. I have found an easily available (in the US anyway) brightener that works for me using sulfuric acid based room temperature bath. Miralax, which is a laxative found in any drugstore or Walmart. It is basically polyethylene glycol powder and worked great for my needs.

I too searched for a long time for a brightener. Dosage is approx. 1 teaspoon per gallon, but I have not determined the optimal amount since it worked for me right away. FYI 0.2 volt.

David Dolata [returning]- Wisconsin, USA

A. With respect to the question on brighteners, polyethylene glycol has been mentioned. The laxative recommended (in fact all PEG laxatives) has quite a large molecular weight, i.e., 3350. What is recommended for plating seems to be lower molecular weight, i.e., shorter chain molecules.

The other brightener I've read about is "Dalacin®" aka sodium saccharin. It can be purchased in bulk from eBay quite cheaply.

Sodium Saccharin on

eBay or

Amazon

(affil link)]

(I understand the chef analogy to requests for proprietary formula ... but the analogy seems to fail when we forget the original poster isn't telling the chef to release his recipe, the OP is asking ... and asking politely it would seem).

Thanks

Doug

- Hamilton, Ontario

November 7, 2020

A. I am just getting started with copper electroforming and have found the many YouTube videos by Jason Welsh most informative. He discusses the use of Polyethylene Glycol (PG) as a brightener and points out a practical issue. Over time you will find that you need to keep topping up the PG in your tank. Eventually this will no longer restore brightness to your pieces. The remedy for this is to pass the entire solution through a carbon filter. After filtering it would be prudent to check the pH and adjust the acidity as required.

Jason's video "Electroforming Brightener Glycol":

I realise that this relates to Electroforming rather than Electroplating but think that it is still usefully informative.

Jeremy Fosker- Colchester, UK

![]() Thanks Jeremy, that is very practical & useful information for non-commercial use, as well as for third-worlders who lack access to established brightener supplies.

Thanks Jeremy, that is very practical & useful information for non-commercial use, as well as for third-worlders who lack access to established brightener supplies.

Still, there are some differences between artistic electroforming and commercial electroplating. For example, there is little or no need for ductility in electroforming, but it is often essential in electroplating: when automobile grill expand & contract as they fry in the sun or trudge through slush, a ductile copper layer between the chrome plating and the plastic substrate is crucial.

Another issue that hobbyists usually do not need to worry much about, but which is critical for commercial platers, is an 'equilibrium process' -- for them it is not just a matter of the plating on one component functioning well, but that the bath stays properly balanced so the second part will plate right, and the million-and-oneth component as well.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Hi there,

I'm from India and run a metal finishing industry. I would like to know how to prepare an acid copper brightener? If you could tell me the chemical composition and method of preparation I would appreciate it.

Thank you,

Mithun Ashok Soni- Mumbai, Maharashtra, India

2002

A. You may begin by consulting a variety of reference books and reading old and current patent literature. Then you can go to the laboratory and test out each of the formulation components until you arrive at the components needed and the quantities required of each. Or, you could call a supplier of proprietary materials who has already done the above and more and would charge a fair price for the benefit of their research and knowledge by selling a proven material.

You might surmise that I am involved in the sales and/or manufacture of proprietary chemistry and you would be right. Do you tell a chef to give you the recipe, you don't want to eat at his restaurant? Do you ask a doctor for the formulation for a drug? Why do you expect to get proprietary knowledge for free?

Gene Packmanprocess supplier - Great Neck, New York

![]() Hello Gene, you're clearly right that some knowledge is proprietary ... but we should probably be gentle. People may not know what is generic vs. patented vs. trade secret, and the other ins-&-outs of the Western plating industry, and may simply assume that what they learned in science class is how plating is actually done.

Hello Gene, you're clearly right that some knowledge is proprietary ... but we should probably be gentle. People may not know what is generic vs. patented vs. trade secret, and the other ins-&-outs of the Western plating industry, and may simply assume that what they learned in science class is how plating is actually done.

"Home-brew", however inferior, is required where there is no commercial distribution of western plating processes (and even in the West when a technology loses its champion -- as happened with sulfamate nickel, cyanide zinc plating, and magnesium finishing processes).

There is a worldwide patent system, the purpose of which is "to incentivize the advance of technology for the good of mankind, by granting temporary financial benefit to those who put in the work"; we are welcome to try to hold information as proprietary forever rather than patenting it, but needn't be offended that people don't inherently understand our business model.

Thanks for helping where you can, as you often do!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

|

A. The formula is: 42% sulfuric acid Put carefully sulfuric acid into the water and let it cool down and then fill also carefully the Nitric acid into. The mixture is not directly to use because it's too hot. The cooling time its up to 24 hours. You can also put 1% of HF(Hydrofluoric acid) or other oxidizer to accelerate the reaction (very very fast but very dangerous in contact with skin) . The fumes they produce are dangerous and are to avoid. Use of PVC for storage are recommended. This mixture are not usable as a bath because in contact with air losing of its strength will occur. Hope this helps. Athanasiadis Stelios- Thessaloniki, Greece 2002

The first response was for ADDING metal - that to get an organic additive for a copper PLATING bath you should go to a reputable supplier who has spent the time to develop such additives. The second response was about making a BRIGHT DIP for copper that will brighten the surface because it REMOVES metal. I think both responses are correct, depending upon how you interpret the question. That is why we need more carefully phrased questions!  Bill Vins microwave & cable assemblies - Mesa (what a place-a), Arizona ? A little ambiguity? Are you talking about a brightener additive for an acid copper plating bath or an acid dip to brighten parts made of copper? Neil BellAlbuquerque, New Mexico |

Q. Hi Chaps, I think such an aggressive response was not called for? This guy probably has no idea where to start looking for a brightener (hence MY presence here) or even if such formulations are even sold!

I'm in South Africa, and can't find a supplier for Brighteners, even on the net; I get redirected here?

Now, shipping a drum of brightener to this country can really raise molecular temperatures within the cranium!

Well asked my friend; wish some polite guy would answer and solve a few dilemmas for me, too. I would love to see a bright piece of copper plating come out of the electroplating bath.

mineral exploration - Musina South Africa

May 14, 2009

A. Hi, Eric. I understand. Unfortunately, I and the majority of readers don't know the answers anyway because they are trade secrets, and you won't find current information in text books these days. In some cases, those brighteners can't be created by simple mixing of raw materials anyway; rather they must be "synthesized from precursors", similar to how plastics are made from crude oil -- which rules out "home brew" anyway.

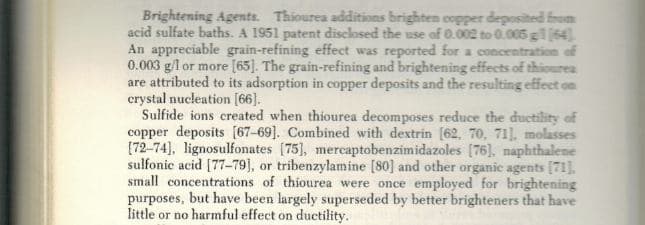

A possible path forward may be to look through old plating books for generic brighteners from "back when". Lowenheim's "Modern Electroplating" from 1942 includes a 2-page discussion of generic brighteners, and it references many different articles on the subject, including many patents, most of which are surely expired by now. (Access to patent info is generally free and reasonably easy these days).

It's not as simple as "try this" though, because each of the referenced possibilities has a list of operating parameters, disadvantages and warnings, etc. Here is an excerpt from that discussion to show the flavor of it:

Best of luck!

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Hi Ted,

Hi Ted,

Thanks for the honest reply, I will try that as a matter of some urgency.

Really enjoy your site and will visit frequently (even if only for being inquisitive by nature).

Cheers

mineral exploration - Musina South Africa

A. Have you tried Thiourea ⇦ on eBay or Amazon [affil link] ? Use it sparingly. Be very careful, this thing will give you pancreatic cancer and damage your bones.

Alfonso Hernandez- Aurora, Colorado

A. Urea 1 g/l and glycerin 1-2 ml/l

Majed Janineh- Beith Lehem, Palestine

October 1, 2011

Q. Dear Majed:

You use Urea 1 g/l and glycerin 1-2 ml/l. May you please tell us how to control their concentration in the bath?

Thank you.

- bogota, colombia

October 8, 2014

Q. Dear All,

Can anybody tell me: What is the role (Chemical reaction) of Brightener in acid copper plating bath?

How does it enable Bright finishing?

- India

August 4, 2009

A. Hi, Saravanababu. Without brighteners, copper plating may grow as rather large crystals in the way of rock candy. These tend to be rather soft, and porous (because there will be 'holes' where these large crystals grow to meet each other), and dull (because of their rough topography).

I don't pretend to truly understand the stereochemistry of exactly what goes on, but brighteners tend to deposit with the electricity, and thus to shield high current density areas first and, by so doing, help to even out plating thickness, and to promote the growth of new crystals rather than enlarging the existing crystals. The process leads to more, smaller, harder, less porous crystals, and brighter deposits. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Hi Mr. Ted,

How does high temperature make brighteners less effective?

- rudrapur,uttarakhand, India

August 1, 2010

A. Hi, Komal

Sorry, I don't know the exact answer to that, or even if there is a universal answer, because different proprietary brighteners might react differently to temperature. But I do know that some brighteners "oil out" (break down into ineffective oils) at temperatures as low as 100 °F, and maybe even lower. Sorry, but I don't know the composition or temperature resistance of the proprietary acid copper brighteners. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. What is the formula of hard copper additive?

Omid Shokri- Karaj, Hashtgerd, Iran

September 18, 2013

A. Hi Omid,

Usually is some polyalkylene glycol related chemistries.

Regards,

David

David Shiu

- Singapore

A. Hard copper brightening is cobalt sulfate.

Hery E- Indonesia

June 22, 2024

![]() Hi Hery,

Hi Hery,

I've never heard of that -- tell us more please :-)

Thanks & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. I am conducting some experiments that involve copper plating of non conductors. I have succeeded in plating them but they appear very dull. How do I increase their luster and surface finish?

Rameez Malik- Rourkela ,Odisha, India

August 24, 2014

A. Hi Rameez. We appended your inquiry to a thread which explains brighteners for acid copper plating. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

A. Surprised no one mentioned molasses. That's right, blackstrap molasses from the grocery store.

Dave Wichern

Consultant - The Bronx, New York

Q. How do molasses work are they in tank or applied post plating and how, etc.?

Brock Mytton- midhurst sussex uk

May 1, 2017

A. Hi Brock. Molasses is a 'brightener' for copper plating; as such, a small amount is added to the solution in the plating tank. Molecules of the brightener are drawn to the high current density areas of the component being plated and tend to slightly shield it away from further plating. By doing so, the plating is more even in thickness, and more adatoms form, for smaller, less porous, harder plating.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q. Delighted for your answer, thank you - is there a go to document on hobby plating, I'm just getting a lot of mush even with low volts and amperage if the thing I bought on eBay is correct (there is only mild fizzing) -- also I'm using copper pipe as anode, and graphite mixed with waterproof PVA for cathode object - is this suitable and/or is there anything else with better conductivity?

Brock Mytton [returning]- Midhurst sussex uk

May 5, 2017

A. Hi again. For a "go to document" see if a local library has the Electroplating Engineering Handbook ⇨

A copper pipe is a poor anode, but it may be useable for hobby purposes. For hobby plating, as opposed to production plating, the pure copper of stripped wire is probably best. Production platers need phosphorized copper anodes (because otherwise the copper concentration builds up relentlessly to where the anodes go 'passive' and plating isn't possible).

One of your issues is that there are a hundred variables in plating, so when you have questionable anode material, questionable cathode, questionable power supply, questionable solution chemistry, questionable instructions, and are getting "mush", it's already a very deep hole to climb out of, and you don't want to start pouring questionable brighteners into that hole :-)

Personally, I would start by getting some small pieces of brass sheet, get them spotlessly clean by scrubbing with a pumice ⇦ on eBay or Amazon [affil link] and detergent solution and toothbrush while wearing gloves ⇦ on eBay or Amazon [affil link] , and try to plate them, because brass is the most plateable substrate, whereas we have no idea whether your particular graphite + PVA article is even plateable. The way forward is to narrow down the list of things that could be causing the problem, successfully or unsuccessfully plating something which is much easier to plate. Good luck!

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

![]() Thank you again Ted, Yes I thought it could be any of a number of individual or cumulative factors! Going to start afresh, thank you for your advice, best regards. Brockie

Thank you again Ted, Yes I thought it could be any of a number of individual or cumulative factors! Going to start afresh, thank you for your advice, best regards. Brockie

- midhurst sussex uk

Q. If one was to use molasses as a brightener in an acid copper sulphate ⇦ on eBay or Amazon [affil link] solution how much molasses would one add per liter of solution?

Joshua Rich- Plymouth, Massachusetts USA

A. Hi Joshua.

Even production platers generally can't analyze for brighteners and must rely on Hull Cell

⇦ huh?

testing (search the site) to determine brightener additions. But it's a very small amount, probably nowhere near a milliliter for a one liter bath. You need sulfuric acid

⇦ on

eBay

or

Amazon [affil link]

as well as the copper sulphate, and ideally about as much thiourea

⇦ on

eBay

or

Amazon [affil link] as molasses.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Q, A, or Comment on THIS thread -or- Start a NEW Thread