-----

Chrome plating onto aluminum

Q. Hi, I own a metal finishing company in FL. I'm looking in to getting into chrome plating onto aluminum. A lot of people are telling me that it is a big thing. I've done chrome plating on steel and brass only. Will appreciate any suggestion.

Tony P [surname deleted for privacy by Editor]polishing shop - Miami, Florida

1996

A. Hi Tony. Aluminum immediately forms a passive film onto which it is not possible to electroplate. Therefore the first step is to apply a zincate coating.

Once the zincate finish is in place you either start with cyanide copper before acid copper-nickel-chrome plating or start with alkaline electroless nickel plating before copper-nickel-chrome instead. The process vendors will be able to give you reprints of shop write-ups from the trade journals. Good luck,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

1996

A. Years ago I was involved in plating aluminum pistons. We double zincated the parts and used Enthone's alkaline EN at a much lower temp than recommended. It has a very strong ammonia ⇦ on eBay or Amazon [affil link] smell. If you try it, buy a gal of stabilizer because it will plate out in a week or so at Miami ambient temp. They can tell you how to use it and it sure is not in the ops sheet. You might even want to put a layer of regular nickel on it because you will have to re-rack, clean and activate unless you are using tank anodes in your chrome. If you find a way to get all of the chrome off of the racks, please tell me because it always seemed to find a spot that contaminated another tank. It takes some getting used to, but plating on aluminum is not all that bad and the EN strike made it a lot better.

James Watts- Navarre, Florida

1996

A. I found 2 ways would work on aluminum, one was after double zincate to use EN strike for parts with deep recesses (such as rims). The other was a cyanide copper strike. Both of these were followed by plating the parts in acid copper, then nickel-chrome.

Ray Salchowmetal finishing shop - Cincinnati, Ohio

1996

Q. Dear All,

Can anyone advise me regarding the hydrogen embrittlement of chrome plated aluminium? I'd like to know how it works and how it can be avoided or solved. Any help you can give will be much appreciated.

Ben B [surname deleted for privacy by Editor]research - Cambridge, UK

2001

A. Sorry Ben, I'm not really familiar with hydrogen embrittlement of aluminum, but see letter 55684, which addresses the subject in some detail.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Hard chrome plating of brass-plus-aluminum guitar tuners

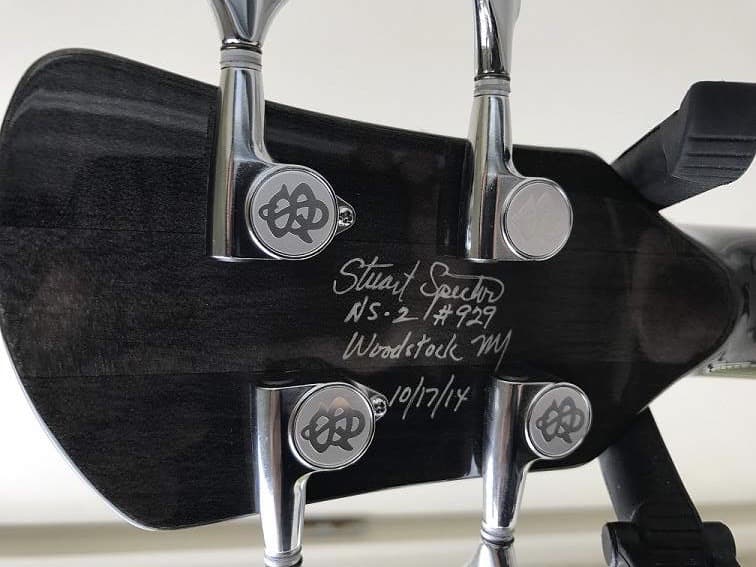

Q. I’m having some guitar tuners hard black chrome plated. The plater said this is better than black nickel The tuners are made of brass with a press fit aluminum dust cover that cannot be removed. The plater called me today to say that there is a 50% chance that the plating will not stick to the aluminum cover. If the tuners stay in the plating solution too long they will seize.

Not sure if I should take a chance and say go for it or if I should cancel the whole job. Hope someone could offer some guidance...

Musician - Pleasantville, New York USA

February 8, 2020

A. Hi Mike. A photo would probably help because I'm not sure what this 'dust cover' is about, but I would certainly cancel if the shop guesses at 50% success. Plus, the term 'hard chrome' doesn't fit with this application -- meaning that a misunderstanding is involved as well.

It is difficult and tricky to plate onto mixed metal construction like aluminum and brass because the pretreatment process is usually much different, requiring masking and de-masking mid-process. New tuners more to your liking would probably be less expensive.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

February 2020

Sending a pic so you can get a better idea...

- Pleasantville NY USA

February 8, 2020

A. Hi. Thanks for the pic. The black chrome plating would probably completely obscure the monogrammed pattern on those dust covers. How about asking the plating shop to mask them before plating, leaving the look of the dust covers exactly as is? They can later get a charcoal tinted clear coat if you wish, which would darken them without hiding the monograms. Although it is possible to clearcoat first, and use the clearcoat as the maskant, I wouldn't chance it on these items. I think it's worth a call to Spector to see if they have replacement tuners, possibly even in black chrome.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

February 2020

![]() Great idea. Thanks!

Great idea. Thanks!

- Pleasantville New York USA

February 9, 2020

Q, A, or Comment on THIS thread -or- Start a NEW Thread