-----

Electrical Resistance/Conductivity Testing of MIL DTL-5541 Chromate

Quickstart:

Aluminum is often 'chromate conversion coated' as a corrosion resistant final finish or as a pretreatment for painting or powder coating. The process actually involves many steps, usually including alkaline cleaning, etching, deox/desmut, the chromate conversion step per se, and water rinses between each step.

MIL-C-5541 / MIL-DTL-5541 / MIL PRF-5541 is the most commonly cited spec. "Alodine" and "Iridite" are proprietary trade names of the suppliers of the process chemistry. In the USA "Chem film" is an often used slang term for the process.

![]()

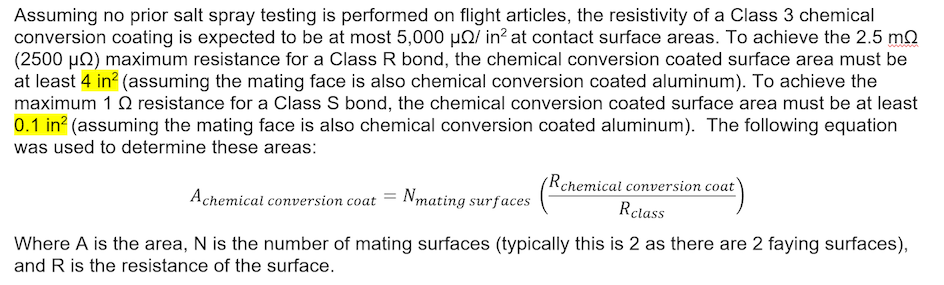

Q. Verifying a Bond Path Analysis equation?

I've inherited a bond path analysis. I have been asked where an equation came from. I thought NASA-4002A.

Can someone validate the equation in the link, and tell me "simply" where it is derived from in the ESD world?

- San Antonio, Texas

September 26, 2023

⇩ Related postings, oldest first ⇩

Q. I am looking for information on chemical conversion coatings on aluminum and aluminum alloys. The issue that is in question is the MIL-C-5541 rev. E Military specification requirement to verify class 3 chemical conversion coatings by running an electrical resistance test per QPL-81706 [⇦ this spec on DLA]. This procedure involves applying an electrode pressure of 200 psi to the coating and measuring for less than 5000 micro ohms per square inch. Our company wants to find a test method that can verify compliance of our stock of parts without elaborate (costly) test setups. If you can help, it would be greatly appreciated.

1995Name deleted at request due to age of posting

A. I would recommend the approach of at least one major aerospace supplier:

In their process specification, they call out the same mil-specs that you do, except that they exclude clear coatings, this makes the identification of a chromated part very easy. If you must use a clear coating, at least specify a blue, slightly iridescent color to make identification easier. The QPL-81706

[⇦ this spec on DLA] is a qualified product list and I would mention it in the specification, and pick one brand to write your specification around, allowing for alternates.

I have never seen anyone use the resistance measurement for chromate conversion coatings. I have seen a simple apparatus using a light bulb and some low voltage source for testing for the presence of an anodic coating on aluminum, since the clear coatings are hard to distinguish visually. But an anodic coating is much harder than a conversion coating and the test is easy to do with a simple method.

I think you should specify the appearance and color for all parts; and corrosion resistance (ASTM B117 ), and coating weight (MIL-C-5541) on a monthly basis for a sample of parts or a test panel, depending on how critical the corrosion resistance is for the parts.

Tom Pullizzi

Falls Township, Pennsylvania

1999

Q. We are in a hurry to know which are the values of: ELECTRICAL CONDUCTIVITY of aluminum 7075 T73 and aluminum 6061 T6 after yellow Iridite treatment.

Thank you very much.

- Madrid , SPAIN

2003

A. The conductivity is a function of the thickness or "coating weight" of the chromate. Our MIL C-5541 specifies Class 3 for low contact resistance, however, in the real world there is a great amount of controversy as to the contact pressure control in actually measuring the contact resistance.

Other presenters will give you a number "value", but I claim there is no reliability in defining this number because of the difficulty in defining a method of controlling the contact resistance.

Robert H Probert

Robert H Probert Technical Services

Garner, North Carolina

A. I agree with the previous gentleman's assessment of how the electrical resistance is controlled, it is a function of coating weight. We have had the need however to provide a recognition that this control is "number related". We worked with our customer to agree on this number by utilizing an instrument to measure electrical resistance. Although we are using a different instruments than our customer to measure electrical resistance, we have agreed that our measurement of what constitutes "low electrical resistance" for his application is acceptable. The instrument that we are using is a simple tool and is relatively inexpensive.

Joe Hillockanodizing shop - Philadelphia, Pennsylvania

A. I disagree with the comments, and one can make consistent measurements using 2 surface resistance probes as outlined in ESD Association's Worksurface Measurement standard. There are also .5 inch diameter probes and miniature probes available for this purpose. When I spec this class of finish I use < than 2 ohms surface resistance and it is and can be consistently measured.

Donn G. Bellmoreinstruments - Binghamton, New York

![]() Thanks Donn. I am no expert in that topic but I trust that the ESD Association is, and that their tests are good ones. The problem I see, and maybe it's a misunderstanding based on my limited knowledge, is that although you feel that you can measure surface resistance in a manner which you consider accurate & repeatable, it does not seem to comply with the spec. Probably the Navy ought to work with the ESD Association to resolve this, but it appears that the current test requires 1 square inch probes, kelvin bridge measurements, less than 0.5 ohms surface resistance, etc.

Thanks Donn. I am no expert in that topic but I trust that the ESD Association is, and that their tests are good ones. The problem I see, and maybe it's a misunderstanding based on my limited knowledge, is that although you feel that you can measure surface resistance in a manner which you consider accurate & repeatable, it does not seem to comply with the spec. Probably the Navy ought to work with the ESD Association to resolve this, but it appears that the current test requires 1 square inch probes, kelvin bridge measurements, less than 0.5 ohms surface resistance, etc.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Is there any specification and test procedures on the conductivity or resistivity of the coating from chemical conversion treatment (eg. Alodine)? Any lead is greatly appreciated.

Asyong Salunggaresearcher - Toronto, Ontario, Canada

2003

A. See MIL-C-5541 or MIL-DTL-81706

[⇦ this spec on DLA]

for test panel preparation and salt spray requirements. The conductivity testing apparatus and procedure are given in MIL-DTL-81706. Conductivity of Class 3 coatings is measured both before and after salt spray testing. Briefly, contact resistance is measured by pressing a flat test panel between polished copper blocks. Both specifications are free downloads at the ASSIST site: assist.daps.dla.mil/quicksearch/ ⇩.

ASTM B449 is similar, but with coating Classes 1, 2, 3 & 4 rather than 1A and 3 as in the MIL specs. Corrosion resistance varies considerably with coating Class and alloy.

Another specification is ISO 10546: 1993 CHEMICAL CONVERSION COATINGS - RINSED AND NON-RINSED CHROMATE CONVERSION COATINGS ON ALUMINIUM AND ALUMINIUM ALLOYS. The abstract mentions electrical resistance and corrosion testing, but I don't have details.

- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

Ed. note Feb. 2025: That MIL specs site is currently https://quicksearch.dla.mil/qsSearch.aspx

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I would like to find out how to carry out the Electrical Resistance Testing on Chromate Conversion Coating for Aluminum as per MIL-C-5541 rev. E.

Hooi Peng CheahManaging Director - Smpang Ampat, Penang, Malaysia

2004

See MIL-DTL-81706 [⇦ this spec on DLA] for the testing apparatus and procedure.

Ken Vlach [deceased]- Goleta, California

Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from.

Q. Has anyone built the required electrical resistance (for chemical coatings) apparatus to conform to MIL-C-81706? Any information on where to obtain the equipment or components would be greatly appreciated. Thanks.

Brian Persing- Springdale, Arkansas, USA

2004

Q. I am developing an aluminum sheet metal part that will be chem filmed and must meet MIL-DTL-5541 [⇦ this spec on DLA] F, CLASS 3. Where can I buy the equipment to measure a resistance not greater than 5,000 microhms per square inch with a nominal electrode pressure of 200 psi?

Mark StauderMechanical Design Engineer - Irvine, California

2007

|

|

A. Build it or buy it! We tried for years to locate such a piece of test equipment and finally we purchased a load cell to measure force, machined a copper electrode 1" x 1", and put the unit into a hydraulic controlled anvil press. Using a simple amp/volt meter between the copper electrode and the test piece we were able to measure the surface resistance. The alternative is to have an outside electrical testing house measure it for you which is often easier and cheaper when you factor in the cost of calibration. Lastly, once you've settled in on a chromate product and defined the process needed to stay below the maximum resistance, you'll find the result doesn't vary. The spec you reference doesn't require that you measure the resistance (whereas AMS2473 might), MIL-C-5541 Class 3 requires the use of a QPL-approved product which has demonstrated its ability to meet the resistance requirement when operated per the manufacturer's data sheet.  Milt Stevenson, Jr. Plating shop technical manager - Syracuse, New York A. Not sure whether these are commercially available. - Goleta, California Rest in peace, Ken. Thank you for your hard work which the finishing world, and we at finishing.com, continue to benefit from. |

Q. Can this apparatus be purchased? If so, where?

Ian Miller- Toronto

July 15, 2008

Q. Do you know of any finishing.com supporting advertisers or independent labs that do conductivity testing?

Kim Price- Springfield, Massachusetts

2006

A. Hi Ian, hi Kim. Dr. Ravi Chandran ran Chemionic Labs & Consulting for years, and featured this test. But he has moved on to other employment unknown to me. If you know someone from the Newark NJ area who might know Ravi, maybe (Dave Wichern or Steve Rudy?), or if you find him on linked-in, etc., by including "Chemionic" in your search, I'm sure Ravi can either run the test for you, send you to someone who can do it, or tell you how to do it.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted is available for instant help

or longer-term assistance.

updated Nov. 2022

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. Hi,

I'm interested to know how or where I can get the equipment for measuring electrical resistance chemical film (Class 3) in accordance with MIL-DTL-81706 section 4.5.5.

Thank you.

With Best Regards

- Singapore

November 30, 2015

A. Sim,

First: Usually this type of testing is only required when you are developing a chemistry for applying the chemical conversion coat. If that is your goal then you are correct that the testing needs to be done before it can be submitted for inclusion on QPL-81706.

Second: In my 32 years in metal finishing I've never seen this equipment offered for sale by anyone. I'm not saying it isn't, but I've never seen it. Companies usually build their own or they send samples out to an approved laboratory that already has the equipment. It would most likely be less expensive to send it out unless you plan on performing the test frequently. The one and only time I've ever been requested to test the coating, I sent samples to a lab in California that performs this test.

Tim Hamlett, CEF

- West Palm Beach, Florida, USA

A. CHEMIONIC Labs & Consulting is ISO17025 accredited to perform this test. We are accredited by American Association for Laboratory Accreditation (A2LA).

Ravi Chandran, Ph.DCHEMIONIC Labs & Consulting

New Brunswick, New Jersey

Ed. note April 2018: Unfortunately, Chemionic Consulting is no longer operating that laboratory -- but Dr. Chandran may still be able to advise on the subject.

Q. I am reaching out to see if anyone in this community may know where I may find the apparatus used to perform Contact Resistance Testing IAW MIL-DTL-81706 [⇦ this spec on DLA] . I have been unsuccessful in my search thus far. This is my last resort before attempting to build one.

Matthew Cunningham- Crestview Florida

August 21, 2021

A. ERPO, based in France, manufactures and sells the equipment to carry out the electrical resistance test as per MIL-DTL-81706. It is called AMES EVO 1.5.

I had the chance to use one because the company I worked for had to do periodic testing with it. It works well.

- Montreal, QC

November 25, 2022

Q. Class 1 vs class 3 resistance measurements? I can see the spec for class 3 as 5,000 micro ohms per sq; but what is class 1? (I saw a thread above that implied 2 ohms per sq). Also, regardless of the surface resistance (in Ohms per sq), does anyone have feed-through resistance in ohms....in other words, does class 3 also have 5 milliOhms resistance to pass through current? And is class 1 has 2 ohms? Any simple ohmmeter measurements of the 2 classes?

Al CormierE3 engineer - Tampa, Florida

May 15, 2023

Q, A, or Comment on THIS thread -or- Start a NEW Thread