-----

Ra surface finish vs. grit conversion chart

Q. I am looking for a conversion chart from English to metric for Ra surface finish values.

Danforth M [last name deleted for privacy by Editor]- Battle Creek, Michigan

2001

A. One (1) microinch equals 0.025 micrometer.

Bill B [last name deleted for privacy by Editor]- Raleigh, North Carolina

2001

2001

A. Danforth,

Here is a copy of the table that we use for stainless steel surface finishes in the pharmaceutical industry. This is included on a fact sheet of useful information for process engineering. If you want a copy, please send me an email, and I will reply with a copy for you.

Surface Finish of Stainless Steel, Ra vs US & UK Grit size.

US Grit UK Grit Ra Ra

ref Ref. µm µ inch

120 3 125

180 2 85

80 1.65 70

240 1.50 50

320 0.75 30

180 0.62 25

240 0.45 18

500 0.40 15

320 0.25 10

Andrew Provan

Bovis Lend Lease Pharmaceutical - Manchester, UK

Q. Andrew,

Thanks for posting the chart. Can you tell us the source of this chart. Also, what about stainless steel mirror surfaces that has a Ra of 1 (ONE) microinch? What are the corresponding US Grit and UK Grit numbers?

Thanks,

Michael Liu Taylor

specialty stainless steel distributor - Dallas, Texas

2007

2007

![]() Excellent! I am still getting one or two enquiries every week on this, despite this posting being some 6 years old.

Excellent! I am still getting one or two enquiries every week on this, despite this posting being some 6 years old.

Please continue to send me emails, and I will respond with either a PDF version of this chart and other useful information...or if you would like a plastic laminated version, let me know your address, and I will put it in the post for you.

Cheers

Andrew

Bovis Lend Lease Pharmaceutical - Manchester

---

Ed. note: Potential advertisers might take a hint :-)

Q. I would like to know the equivalent finish of root of 32

Gaurav DodiaProduction Engineer - Pune, Maharashtra, India

March 31, 2008

A. Hi, Gaurav. It's not exactly a square root sign, it's a finish mark sign, which looks half like a check mark and half like a square root symbol. Lacking any other notes it probably means 32 microinch RMS, I think. You could consult a drafting standards book like

French's Engineering Drawing for a fuller understanding of this kind of drafting note if interested. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

March 31, 2008

Q. Hello,

Thanks for the chart, it really got me rolling with one of my current projects.

Do you have any information regarding the difference between valley's in steel = x Ra versus peaks on the surface = x Ra?

thanks

- West Bend Wisconsin

April 1, 2008

Q. Does someone have a chart of Ra32=US grit?

thanks

- Garland, Texas

December 9, 2008

December 10, 2008

A. Hi, Dow. The approximate answer is already on the page. Ra25 = U.S. Grit 180 and Ra70 = U.S. Grit 80. You can interpolate to a reasonably close number I think. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. Hi

I'm looking for an example of a 100 grit (number 3) finish for stainless steel. Can someone upload a picture and draw some equivalent for me?

Thanks,

Angela

- Los Angeles, California

March 20, 2009

A. Hi, Angela

Surface finishes are 3-dimensional, so a picture will not do much good. Rather, you can buy a "comparator"; this is a sheet of electroformed metal which is divided up into like a bingo board, with one area finished to 100 grit, and with other grit sizes above and below for comparison.

Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

August 4, 2010

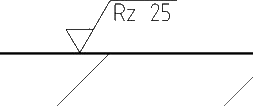

Q. I am working on quoting a machining part that is currently being made in Europe.

The problem is the print info. is all in another language. There is a symbol for a microfinish that the line goes up and then straight right and under the line there is Rz 25.I have been looking all over the internet with no success. Does anyone have any ideas on what it means or where else to look.

Estimator - Jackson, Michigan USA

September 22, 2010

January 16, 2011

A. Hello Tim,

Have you already found the information about Rz parameter?

This one is typical for old designs based on GOST 2789-73 "Surface roughness. Parameters and characteristics".

Following this standard, Rz is the height of roughness by ten points. On a base length one can find 5 profile maximums (highest lugs) and 5 profile minimums (deepest cavities). Rz is 1/5 of the sum of these.

There are following correlations between Ra and Rz depending on the processing method:

for turning: Rz = 5Ra;

for grinding: Rz = 5.5Ra;

for polishing: Rz = 4Ra.

- Ilmenau, Germany

Q. What is the surface roughness achieved by using 320 and 400 grit abrasive belts on steel and chrome?

Amol Nanavati- India

February 28, 2012

Q. What is 35RA polish finish for stainless steel T-316 ss?

Alex Roman- Corona, California

June 27, 2013

November 14, 2013

Q. I am trying to achieve a 32 surface finish on aluminum 6061-T6 block. Can you tell me what sandpaper grit I should use (I'll do it by hand).

Todd Wilson- San Diego, California

December 17, 2013

Second Request

A. Before anyone can answer your question, we need to know what you are starting with. Most mill stock metals are finished to between 32-36 RMS, so unless you did some machining, you are already there.

AF Kenton

retired business owner - Hatboro, Pennsylvania

December 19, 2013

Q. The raw aluminum extrusion gets an angled saw cut.

Todd Wilson- San Diego, California, USA

December 20, 2013

A. Hmmm. Saw cut could be very rough; therefore, that is still not enough info to give you a one step correction. My guess is that you might want to start out with a 60 grit belt. You will end up with either an 80-90. Maybe 120 as the finest.

AF Kenton

retired business owner - Hatboro, Pennsylvania

December 25, 2013

Q. Can you tell me if there is an industry Standard or professional association definition of the range of surface roughness average (Ra) attributed to the grit finish for stainless steel? Specifically, I am looking for an industry recognized standard for the range of Ra values for 80-grit Stainless Steel.

Thank You.

- Philadelphia, Pennsylvania

August 15, 2014

A. Hi Kevin. Andrew has already given us a chart showing Ra of 70µin for 80-grit stainless steel. I'm not quite understanding what you are looking for beyond that. Can you explain your situation? Thanks.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

August 2014

Q. Does anyone have a copy of the fact sheet that Andrew mentioned in the 2001 or 2007 posts?

Scott Grimshaw- Norfolk, Virginia USA

May 19, 2015

![]() Hi Scott. The implication of your posting is a bit vague. Are you implying that the posted e-mail address now bounces, or he asked you to stop bothering him? He is on Linked-In, and apparently is currently with exmoorpharma.com, but I don't want to contact him or have others contact him if he requested that people desist :-)

Hi Scott. The implication of your posting is a bit vague. Are you implying that the posted e-mail address now bounces, or he asked you to stop bothering him? He is on Linked-In, and apparently is currently with exmoorpharma.com, but I don't want to contact him or have others contact him if he requested that people desist :-)

Thanks for any update.

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

May 2015

May 29, 2015

Ted,

When I emailed I got an error screen that said the email doesn't exist. I just figured that since it was so old that maybe things had changed.

I am still trying to locate a copy of that chart though and any help you can provide will be greatly appreciated.

Thank you,

- Norfolk, Virginia USA

Q. This thread is quite old, and Andrew Provan is no longer reachable. But evidently there is an ongoing need for this information. If anyone has the document, could they please post it to Eng-Tips.com? Metals & Metallurgy section.

Thanks!

Metal Fabrication - Sarnia Ontario Canada

December 7, 2018

Ed. note: ... or just e-mail it to

Q, A, or Comment on THIS thread -or- Start a NEW Thread