-----

Environmental hazards associated with chrome plating

Q. In the process of up-dating our business plan, we are seeking a concise article or paper on why chrome plating is considered to be environmentally hazardous and the impact this may be having on the industry.

Cliff Harper- Castlegar, BC Canada

2000

A. I doubt that you're going to find a single paper that covers all of the important elements of the issue. And, from the way that both sides instantly dismiss facts to spin things and race to their ideological extremes, there is little chance of coming up with a realistic economic impact analysis.

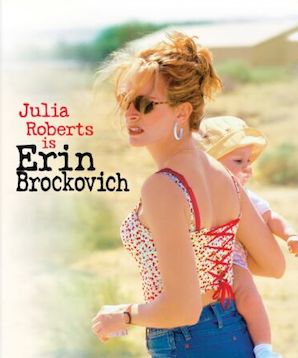

Compounding those problems is yet another -- that the cost to industry will be proportional to the dangers that the public perceives, irrespective of actual facts. To make this point in a rather silly but telling way, I can simply ask: "Do you want that economic analysis based on the presumption that Julia Roberts will win the Best Actress Oscar for Erin Brockovich this year, or that a different actress will win the Oscar?" The truth is, public opinion against hexavalent chrome will be much stronger for years to come if she wins, and less strong if she loses :-)

The chrome plating itself is not toxic in any way, but most decorative chrome plating, and all hard chrome plating, is done out of baths of hexavalent chromic acid. This material is considered a carcinogenic inhalation agent by the U.S. government, and has been known to be toxic and the cause of chrome sores, chrome ulcers, and perforated septums since 1928. Further, it is very hard to keep that chromic acid all in the tank because of the gassing & fizzing which tend to send the material up the exhaust system, over the rims of the tanks, and settling on the overhead rafters, although fume suppressants help greatly. Improper disposal has created some horrendous Superfund sites. It is a major problem that will not go away!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

2000

A. In the USA there are many environmental issues surrounding chrome plating; I am not sure which, if any, apply to your situation in Canada, but these may give you a direction to find information.

In general, the solution itself is considered hazardous under OSHA and the Superfund Amendments and Reauthorization Act (SARA) due to acute (corrosive) and chronic (carcinogenic) health hazards, and fire (oxidizer) hazard. The spent solution often is considered hazardous under the Resource Conservation and Recovery Act (RCRA) for corrosivity (pH < 2) due to the acid content and usually for heavy metals (chromium and on occasion for other metals depending on the nature of the substrate). The rinse waters often are regulated as well, depending on the composition and method of discharge.

These regulations carry with them (depending on factors such as quantity stored, consumed, disposed, etc.) numerous reporting requirements: hazardous waste reports (usually every other year) describing nature and quantity of waste, location and nature of waste handling; contingency reporting (generally methods used to protect the environment, workers and surrounding population from exposure); toxic release reporting (annually) describing disposition of specific listed chemicals (chromium compounds and nitric acid) to all media (air, water, on-site and off-site treatment, recycling, and "release"-including regulated and permitted waste disposal); and hazardous chemical inventory reporting (annually) describing quantity, location and method of storage.

In addition, several permitting requirements apply, which vary with local and state regulations and specific application as to nature of discharge, if any, to air and water.

- Pittsburgh, Pennsylvania

2000

Environmental impact from chrome plating process

November 10, 2016Q. Hi!

I am currently gathering information about chrome plating for an environmental assessment/comparison, and I have a hard time trying to find information on resource and energy use connected to amount of produced output.

I am primarily interested in decorative chrome plating but hard would also be interesting, or qualitative differences between them, on this issue.

If I understand it right then the best way of measuring produced output would be chrome plated area.

So basically I am asking for an assessment of the total energy use, including supporting processes, for chrome plating one square meter (for a few commonly sized industrial operations, if size of operation has a big impact). I would also be very glad if I could get waste data on the format (per square meter chrome plated material).

(To get data "per square meter chrome plated material" it is probably easiest to estimate the total output per year (or month) and combine that with knowledge of energy use/waste produced per year.)

Thankful for any information on the subject!

Environmental researcher - Göteborg, Bohuslän, Sweden

A. Hi Jonatan. Ironically, as an expert witness on a legal case where a defendant was trying to limit his liability for chromium ground water contamination by apportioning it between himself and previous & subsequent shop owners, I once estimated the square meters of chrome plated under the different ownerships based on the utility bills -- essentially working the problem in the opposite direction.

Your problem, as I see it, in trying to work from salad bowl data such as the total annual energy and resources used by a plating shop which plates a certain amount of square meters per year is that there are so many variables that you might find a 10:1 range between two shops.

To limit those variables it might be best to consider the chrome plating step, per se, a unit operation and the nickel plating before it a separate operation, and the polishing, cleaning, activating, etc. as their own operations, too. Although there will still be a lot of variables when looking just at the chrome plating step, there are then some scientific facts & some common practices that we can start with ...

We can determine the approximate required voltage based on the conductivity of the solution and the anode to cathode spacing. We can determine the approximate ampere-hours consumed based on Faraday's Law and estimated plating efficiency. We can estimate the energy consumed in heating the chrome plating tank and in ventilating it based on common practices. We can estimate dragout volume and calculate how much reducing agent and neutralizing agent will be required to treat the wastewater. I think just trying to establish the framework for such calculations would be a noble PhD project though or sufficient fodder for a technical author to write a good-sized book. I think it can and should be done but that we are a very long way from being able to offer data per square meter of chrome plated that meaningfully incorporates the necessary variables.

Meanwhile though, I hope some readers can offer you examples of energy usage vs. square meters plated. I'd love to see some real progress in this area of your interest :-)

Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

November 2016

November 10, 2016

A. One must now also include the energy it takes to bring the Cr6+ in the air down to below 1 ug/m3, as OSHA now mandates.

Great story, Ted.  Dave Wichern Consultant - The Bronx, New York November 2016

|

Q, A, or Comment on THIS thread -or- Start a NEW Thread

on eBay

on eBay