-----

Titanium plating (Electrodeposition OF titanium)

Q. Hi, I'm Samson, from Licungo Beira Mozambique University, I want to do the electroless deposition using 30% Ti(Cl)3 in equilibrium with hydrochloric acid in carbon steel, how to do it?

Samson JoangueteEstudante da graduação - Beira, Sofala, Mozambique

October 26, 2021

A. Hi Samson. We've published your posting and other readers are welcome to reply, but I don't think it's possible.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. And if I try to put a stabilizer in the Ti3+ solution in order to strip the electrons from the titanium, or on the other hand if I put a reducer capable of reducing the Ti3+ to Ti0, this reducer will have a lower reduction potential than the titanium, it may work ?

Samson Joanguete [returning]Estudante da graduação - Beira, Sofala, Mozambique

A. Hi again Samson. You may surprise us, and I hope you do, but to my knowledge it is not possible to electrodeposit or electrolessly deposit titanium from an aqueous solution.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Hi, I want to make titanium electrodeposition, but I will use this recipe, Recipe 3:

30 gm Ti (in the form of TiCl3 or TiI3)

200 ml of toluene 0.02% pitch (?)

800 ml of ethyl alcohol

18 °C, 21A/dm2, graphite anode

But I'm not getting it due to the procedure, can you help me?

I don't know the procedures or the concentration of ethyl alcohol to use.

Estudante da graduação - Beira, Sofala, Mozambique

by Abner Brenner

on eBay or Amazon

or AbeBooks

(affil link)

A. Hi again Samson. It seems to me the ethyl alcohol would have to be 100% because, for the 3rd time, aqueous electroplating of titanium does not seem possible with our current knowledge. You can certainly keep trying if you want, and I wish you success. :-)

But see if your university has Abner Brenner's Electrodeposition of Alloys, which attempts to reference and summarize all those early claims; and study the newer claims here on these pages.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

![]() Thanks

Thanks

Estudante da graduação - Beira, Sofala, Mozambique

A. Listen to Ted, please.

Brett Manko- Florida

A. There are 2 Russian patents on water-based titanium plating somewhere on that forum. Russians published at least 2 books on solvent based electroplating. Hope it helps and good luck!

- Cerovski vrh Croatia

March 1, 2022

A. Thanks, Goran! Two notes here though:

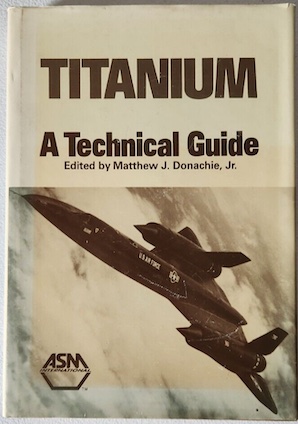

1. Yes, it is possible to electroplate some metals from molten salt baths and/or solvents which, due to electrolysis of the water into hydrogen and oxygen, cannot be plated from aqueous baths. However, these days PVD processes seem to me a simpler and more reliable route.

2. Many early Russian electroplating books, as well as some English-language ones, have been found to contain substantial factual errors about what the processes delivered. As Brenner notes, sometimes this wasn't a result of intent to deceive, but analytical limitations which misled optimistic researchers: metallic titanium wasn't deposited, rather titanium compounds were occluded in the deposit.

Unfortunately I have not learned Russian and cannot comment on the references which you have quoted here, but I'm not personally aware of any theoretical reason that would make it impossible to electroplate titanium from solvents. Thanks again!

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

I happen to be able to read Russian, and, unfortunately, all this book says is that electrodeposition of titanium from aqueous solutions is difficult/impossible (thin coating has been deposited onto copper, platinum, and lead, but apparently only because an alloy of titanium+base metal formed on the surface).

I happen to be able to read Russian, and, unfortunately, all this book says is that electrodeposition of titanium from aqueous solutions is difficult/impossible (thin coating has been deposited onto copper, platinum, and lead, but apparently only because an alloy of titanium+base metal formed on the surface).

It further suggests using titanium chloride solutions in ethanol (possibly with addition of a bit of toluene or acetone

⇦ on

eBay

or

Amazon

[affil links] Warning! Flammable!

), other alcohols, ethers, or DMSO (apparently a solution of DMSO+ethanol works as well). However, even with these, only very thin coatings are mentioned. There's a bit of speculation that maybe having sodium and/or fluoride ions in the solution can be detrimental to the process, and further mention of trying other titanium salts (i.e. not chloride), before moving on to niobium (which is apparently even more challenging).

But, the main point remains: electrodeposition from aqueous solution is mainly a bust, and no handy recipe is offered.

- Pittsburgh, Pennsylvania

October 28, 2022

⇩ Related postings, oldest first ⇩

Q. Dear sir,

Is titanium plating the same with term 'Cladding'? How can I apply Titanium plating to plastic mould or steel to strengthen its hardness. Do you know where can I learn or practice such thing because I work in the manufacturing company that makes spare-parts like gear, mould, cutting blade, etc.

Thank you Best regards,

- Utrecht, Netherland

2002

A. Titanium is a very active metal which cannot be electroplated (out of a conventional aqueous bath). Cladding is a physical process where a skin of titanium is mechanically bonded to the substrate. But you are most likely talking about a vacuum deposited layer of titanium nitride.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. By titanium coating do you mean titanium nitride? If so, it is not the same as cladding. Titanium nitride (TiN) is deposited by either chemical or physical vapor deposition. Cladding is more of a mechanical bonding process, and involves much, much thicker coatings. TiN and similar coatings are used extensively on cutting tools and wear components because the coatings are very hard (>2000 Hv) and very wear resistant. They are also used as decorative coatings on such items as faucets and door hardware because a wide range of colors, all the way from satin nickel to bronze, can be produced without changing the set-up (only the relative amount of process gases needs to be changed). Because the coatings are very thin, it is easy to maintain tolerances.

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

A. 'Body jewellery

Physical vapor deposition is often used to produce black implant-grade, autoclavable body jewellery. Biocompatible titanium coating is vaporized in an arc then electrically deposited on stainless steel jewellery.'

Copy-pasted from the bottom of the wikipedia article

Daniel Williams- Bloomington, Indiana

October 21, 2008

RFQ: I need to do 25,000 S.S. material rod to Titanium Plating which is .154 " diameter & 6 " long so please give me price. Thanks

Shah Vijay- Cypress

2004

A. Your inquiry is a bit vague considering the comments that it is a follow-up to. You understood that you cannot electroplate titanium onto these rods? So, are you looking for mechanical cladding, or for vacuum deposition (and, if so, pure titanium or titanium nitride)? Is there a spec to comply to that would give people an idea of the thickness and the proposed purpose of the coating? Thanks!

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. I have asked this question before but received unclear responses due to the confusing question I posed. I would like to know if Titanium can be electroless or electroplated onto steel and cast iron? Thank you very much for your time. Mark

Mark Robidoux- Malvern, Pennsylvania

1999

A. No. Titanium cannot be electroless or electroplated onto steel and cast iron. Titanium is too active to electroplate. However, some alloys containing a small amount of titanium might be electroplatable; I'm not sure. Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Titanium can be deposited on steel or cast iron by PVD processes.

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

1999

A. Titanium can be electroplated from water based solutions and also from non-aqueous solutions.

Recipe 1:

70 gm sodium metatitanate

30 gm sodium acetate

30 gm sodium hydroxide

1 lit. water, 30-70 °C, 1-5 A/dm2

Recipe 2:

100 gm Ti(OH)2

40 gm HCl

100 gm NH4Cl

water 1 lit.,pH 4-5,30-50 °C, 3-4 A/dm2

Recipe 3.:

30 gm Ti( in form of TiCl3 or TiI3)

200 ml toluene 0,02 % pitch(?)

800 ml ethyl alcohol

18 °C, 21 A/dm2,graphite anode

All from Russian book L.I.Kadaner:Galvanostegija (electroplating handbook), Kiev 1964.

- Cerovski vrh Croatia

2003

![]() You never cease to amaze me with your reference material, Mr. Budija! So I really am curious -- but these formula don't seem to offer any exotic solution to the problem of plating so active a metal, and I have to wonder about their validity. I hope someone tries them and gets back to us, but there has been erroneous stuff published in plating textbooks from time to time and my guess is this is one example :-(

You never cease to amaze me with your reference material, Mr. Budija! So I really am curious -- but these formula don't seem to offer any exotic solution to the problem of plating so active a metal, and I have to wonder about their validity. I hope someone tries them and gets back to us, but there has been erroneous stuff published in plating textbooks from time to time and my guess is this is one example :-(

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Very late response to Mr.Mooney! I am just metalwork restorer, and once upon a time I have this book in my hands. Sorry for my [limited] English.

Goran Budija- Cerovski vrh Croatia

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I need to Titanium plate onto stainless steel. Having never attempted this I need some suggestions.

D. Prickettcorporate recognition awards - Grand Rapids, Michigan

2003

A. Hi, D. You can't electroplate (in the conventional sense) titanium. The hydrogen in the water of solution will be reduced long before the titanium will be reduced.

It is not impossible to deposit titanium or any alloy of titanium in some fashion; in fact, titanium sputtered stainless steel sheet is commercially available -- but please explain what you are trying to do because conventional electroplating is impossible. Maybe it's titanium nitride vapor deposition (gold colored finish) that you are looking for?

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

A. Electroplating or electroless plating - no chance. However, try vacuum deposition technologies.

Trevor Crichton

R&D practical scientist

Chesham, Bucks, UK

A. What type of titanium plating are you looking to do on stainless? We supply titanium plated SS sheets (Type 300 series).

Thanks,

Michael Liu Taylor

specialty stainless steel distributor - Dallas, Texas

? Michael, by what method are you "plating" SS. Clad-ok, PVD-OK. If electroplated I am with Ted, basically impossible, at least commercially.

James Watts- Navarre, Florida

----

Ed. note: Michael's company offers, among other things, gold-colored titanium-nitride coated stainless steel sheets. The titanium nitride is applied by PVD.

A. Titanium electroplating recipes:

I. 70 gm sodium metatitanate

30 gm sodium acetate

30 gm NaOH

Water-1 lit, 30-70 °C, 1-5 A/dm2

II.100 gm Ti(OH)2

40 gm HCl

100 gm NH4Cl

1 lit water,pH 4-5,30-50 C,3-4 A/dm2

from L.I.Kadaner: Galvanostegia (Electroplating) , Kiev 1964.

- Cerovski vrh Croatia

![]() Gentlemen:

Gentlemen:

Reading the full list of responses reminds me that the proper answer might reasonably be, "We cannot do it TODAY, but tomorrow the technology may allow it to be done." I would have agreed with all those who said it cannot be done, until one person steps up and says that it can. I am definitely going to file those ideas permanently.

Thank you,

Ed Budman [deceased]

- Pennsylvania

With deep sadness we advise that our good friend Ed passed away Nov. 24, 2018

A. Sorry for being a little late on this response folks. However, some useful discoveries were made in the mean time, so you could thank me for that!

The original question regarding Ti was not about Ti at all (when I checked into it last time, couple of months ago.) Some people think (or call) titanium nitride or other decorative compounds of Ti as Ti. The person was looking for gold and other color coatings. So when someone asks for Ti plating next time, let's have our question ready, what color is it?

- Fort Collins, Colorado

Q. I still am curious about Mr. Budija's recipes, and can only add that the older I get the more I learn there's always more that I ignore. Just one question to him and all the chemists out there reading this, since the chemicals he mentioned are really not exactly my field: About formula 2, can an alkaline salt Ti(OH)2 be added to an acid solution of chlorides with a pH of 4-5 without precipitating its metal? Will the alkali be partially neutralized and water and titanium chloride form?

Thanks,

Monterrey, NL, Mexico

2004

Q. I was doing a preliminary search on the feasibility of electroplating titanium onto Nickel and came across this message board.

Has anyone attempted the recipes proposed by Goran Budija, or confirmed the validity of the referenced material?

Its been about a year since the post above, so if anyone has had success during that time it would be great to hear about it. Thanks.

- Waterloo, Ontario, Canada

2005

![]() Hi Ryan. Personally I don't think Goran's formulas have any chance of working, but no one so far has tried them and told us the results ... unless you count Abner Brenner in his Electrodeposition of Alloys, which completely discounts those sources, noting that it may not have been deliberate deception, the researchers may have been fooled by tests for titanium that found occluded titanium oxide dusts.

Hi Ryan. Personally I don't think Goran's formulas have any chance of working, but no one so far has tried them and told us the results ... unless you count Abner Brenner in his Electrodeposition of Alloys, which completely discounts those sources, noting that it may not have been deliberate deception, the researchers may have been fooled by tests for titanium that found occluded titanium oxide dusts.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Dear sirs, I am very confused about titanium plating on bronze or aluminum products, and it is a very big fence, so we have to plate titanium separately, but we will have to weld them together, how to plate titanium on the surface where we weld, or is there any way to cover that part just like titanium plating? I'd be great appreciate if I can get your answer

Della Licasting company - Shanghai, China

2005

A. Sorry Della, you cannot plate titanium out of a water based bath. It can be done with some very special equipment from an organic based bath, but it is expensive and limited to much smaller parts than a fence. You can basically forget welding any plated part. weld and then plate. Touch ups like brush plate on weld over plate are ugly!

Virtually anything other than galvanize or plastisol or vinyl coating or paint/powdercoat are going to be very expensive [for a fence], even in China.

- Navarre, Florida

A. Jim W

I was involved a few years ago with a Canadian group that was working on a wet chemical plating system that could deposit titanium (as well as aluminum), but I'm pretty sure they're a long way away from production work. Titanium can be vacuum deposited, so Della may be calling that a plating, as the term ion plating is often used for vacuum deposition processes. However, your answer holds even more so for ion plating -- no way to touch up the weld areas, and even if you could you'd still have to put the entire object in the vacuum system. If you're going to do that, assuming that such a vacuum chamber exists, you might as well coat after welding.

Jim Treglio - scwineryreview.com

PVD Consultant & Wine Lover

San Diego, California

A. Jim T.-- You are correct. I got sidetracked into thinking of aluminum plating. The correct reply should have been that there are no commercial methods of electroplating titanium on any metal.

James Watts- Navarre, Florida

Q. I am new to this site and I have a question about Titanium plating as well. Can smaller objects, specifically rings be plated and if so how durable are they? How would one go about plating with Ti?

Marisa Desoff- Troy, Michigan

2007

Q. I am a student of Ph.D. (Chemistry)In Quaid-i-azam University Islamabad. I want to electroplate titanium on stainless steel. I do not know how it is done. I want to ask the procedure and possibilities of the reaction.

Java Intruderstudent - Islamabad, Punjab, Pakistan

2004

A. Most of us think that it cannot be done, but if you read earlier letters in this thread, you will find possible recipes. If you try it, let us know if it worked for you.

James Watts- Navarre, Florida

A. About titanium plating, I know that some peoples are actually working on a titanium plating process in organic media, at room temperature. Will it work properly ? Do coatings made with this process offer performance enough for industries requirements? I don't know. However, as far as I know, preliminary tests were promising.

Moreover, as with Ted, that Titanium plating bath recipe presented on that discussion list left me speechless. This is the first time that I'm seeing a titanium plating bath made with water. My curiosity have been tickled and I will surely try it.

- Boucherville, QC, Canada

A. Aluminum is electroplated commercially. Siemens patented this back in 1978. The formula they present in the patent uses toluene as one of the constituents. It seems to me that the issues with electroplating aluminum and titanium are similar - so why shouldn't the solutions be similar?

David Ruben- Tempe, Arizona

![]() Thanks David. I'm familiar with the fact that aluminum is being plated commercially. Although aluminum and titanium share the similarity of being more electronegative than hydrogen, 'similar' is context sensitive, and apparently they're not similar enough to be plated out of the same or 'similar' plating baths, although as Daniel says, they're working on it.

Thanks David. I'm familiar with the fact that aluminum is being plated commercially. Although aluminum and titanium share the similarity of being more electronegative than hydrogen, 'similar' is context sensitive, and apparently they're not similar enough to be plated out of the same or 'similar' plating baths, although as Daniel says, they're working on it.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

(you are on the 1st page of the thread) Next page >

Q, A, or Comment on THIS thread -or- Start a NEW Thread