-----

Zinc and galvanized countertops Q&A

Q. We found old workshop metal counter top buried. Can we clean it and use it in a kitchen? Please.

The Dusty Dog- Utah

July 9, 2022

Tip: This forum was created to build camaraderie through sharing of tips, opinions, pics & personalities.

The operator & readers who are here for that often won't engage with anonymous posters.

A. Hi Dog. If you can find out exactly what it is made of, possibly. But although "waste not, want not" is a good adage, when you don't know exactly what something is, where it was from, or why someone thought it was a good idea to bury it, it doesn't sound like a good idea to use it as a food preparation surface. It might, for example, be plated with toxic cadmium :-(

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Multiple threads merged: please forgive chronology errors and repetition 🙂

Q. I am interested in having a zinc metal countertop put in my kitchen and would like an antique finish applied (distressed). Is zinc metal safe to have as a countertop, is it expensive to install and what is the upkeep on them? Any info is helpful.

Kelly C [surname deleted by Editor due to age of posting]Interior decorator and faux finisher - Marietta, Georgia

2003

Q. I am considering using galvanized sheet metal for my kitchen countertops and backsplash and need to learn about caring for the surface. What sort of sealants, oils, or waxes will prevent staining from foods and spills?

Nancy B [surname deleted by Editor due to age of posting]home owner - Austin, Texas

2003

A. Hi Kelly & Nancy: Zinc is an essential nutrient, not a toxin or poison, but zinc is not actually considered "food safe" for pots and utensils because enough can theoretically dissolve into acidic foods to comprise an overdose. I think solid zinc metal is considered safe enough, but wet or acidic foods like cut vegetables might pick up a metallic taste.

However, I do not think galvanized metal is necessarily safe unless you are confident of its origin. Galvanized metal is steel sheet (which is magnetic) that has been dipped in molten zinc and sometimes has a chromate conversion coating (read that as toxic hexavalent chromium). Although it's a very very small amount of hexavalent chromium, I wouldn't choose it for a food surface.

Although it's probably possible to apply a two-component automobile clearcoat to either material to prevent food from touching the metal surface, I don't really think "paint", even clear paint, belongs on countertops. So Kelly yes, zinc is okay; and Nancy no, galvanized is not okay (although I've seen it in restaurants on top of divider walls and as kick plates at bars). Remember, this is just personal opinion; there may be government epidemiologists studying the question but I doubt it.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. We are so very interested in anyone having any information about zinc countertops. How to get them, who will fabricate them, and how to age them! We have a Tudor style 1917 home, we want the old sinks and appliances back, and aren't the least bit interested in granite. We are grateful for any info.

(P.S. I believe there are zinc countertops with brads on the edges in the movie Meet the Fockers

[affil linkaffil links]-- these are what we want and believe belong in certain areas of our kitchen.)

Happy to share any serious restoration resources we have accumulated!

Thank you, Maggie & Matt

- Omaha, Nebraska

2004

Ed. note: Hi Maggie & Matt. You can post your inquiry as an RFQ, making your contact info available to vendors to privately contact you.

And they can be found on Google or are welcome to advertise here of course. But, apologies -- for a bunch of time-proven reasons -- we can't publicly post sourcing suggestions ( huh? why?).

A. I am looking for a new zinc countertop, having had one in a rental house years ago and liked it very much. I used Vim

⇦ on

eBay or

Amazon [affil link]

/Ajax

⇦ on

eBay or

Amazon [affil link] /Comet

[affil link] to clean it; although it probably is not recommended, it did not damage it in any way.

Hope this is helpful to someone.

- Kamuela, Hawaii

2005

Q. To Maggie J (and all others!)

Wondering if you ever located a source for zinc countertops? I, too, am on the search - was first looking for pewter, but have only found one supplier - in Normandy France! 5X the cost of granite, before shipping and installation (gulp!) So now I'm on the hunt for zinc... seems to be very hard to come by in the NW, which is OK, if I can find a reliable source somewhere in the US.

Thank you!

- Portland, Oregon

2005

Ed. note: Sorry that we can't be all things to all people, Toni, but we had to go back and remove all supplier names as we got buried under spam, had suppliers insulting other suppliers, sales people pretending to be satisfied customers, etc. This forum is essentially anonymous and allowing commercial benefit from self-serving postings in this age of spambots simply doesn't work ( huh? why?).

But some suppliers of zinc sheet who posters had mentioned, and which can be neither recommended nor dis-recommended, are Belmont Metals, Brooks Custom, Columbia Metal Products, MetalTech USA, Mio Metals, Rapid Materials/Umicore, and Rotometals. Good luck.

Q. I tried to find an answer to the various questions on how to distress a zinc metal countertop.

I am very interested in knowing how I can accomplish this myself. The zinc sheet

⇦ on

eBay or

Amazon [affil link]

is a blue grey currently. I want to distress/age it - very much so. I understand various acids, i.e. vinegar

⇦in bulk on

eBay

or

Amazon [affil link] , etc. will do this.

I would like to know and would greatly appreciate any food-safe suggestions you may have.

Thank you,

Homeowner - Brampton, Ontario, CANADA

2005

A. Mona: The blue-grey color, and some miscellaneous scratches that your zinc may suffer, probably already comprises the distressed look for zinc. You could try a strong solution of table salt & vinegar and see what darkness & mottling that adds, but zinc doesn't turn green or brown like, for example, copper or brass.

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. Through experimenting on a piece of zinc for a countertop, using different types of food-safe acids, i.e., vinegar, lemon, I have so far found, tomatoes (from a can) to be the most distressing.

Mona F [returning]

- Brampton, Ontario, CANADA

![]() I have installed solid zinc benchtops in my period home in France and it looks fantastic. Be aware that zinc tops are a 'working' surface it will be effected by various foods (acids and alkalis) causing light and dark discolourations - I personally love this characteristic as the hues are usually rich and the look changes constantly. You can however periodically buff the surface back with a buffer or very light graphite paper if you want to get it back to a uniform finish or apply a metal sealer if you don't want the finish to change.

I have installed solid zinc benchtops in my period home in France and it looks fantastic. Be aware that zinc tops are a 'working' surface it will be effected by various foods (acids and alkalis) causing light and dark discolourations - I personally love this characteristic as the hues are usually rich and the look changes constantly. You can however periodically buff the surface back with a buffer or very light graphite paper if you want to get it back to a uniform finish or apply a metal sealer if you don't want the finish to change.

The treatment or aging of zinc is called patination. The zinc reacts to various chemicals. You can artificially age the zinc with different effects depending on the chemical and pattern of sanding / buffing and application of the chemical. The effect I used on my benches was achieved with copper sulphate

⇦ on

eBay or

Amazon [affil link] (you can usually buy it from a chemist) which give the zinc a rich dark patina (the more you use the darker it is) - just buff it in with small circles - and if you don't like the effect you can always buff back and try again.

- Toulouse France

November 20, 2011

! You can make your own zinc countertops. There are several sources of zinc sheet

⇦ on

eBay or

Amazon [affil link]

on the Internet. My wife and I made our own huge zinc-covered kitchen island and backsplashes. Make the substrate from MDF or particleboard like you would for any laminate. Cut the zinc sheet to approximate size by scoring with a utility knife

[affil link] like you would laminate or use shears for little pieces. Glue it with contact cement

[affil link], same as for laminate and roll it down really good with a j-roller

[affil link]. The edges are then trimmed with your router and a laminate blade. This makes a big mess just like laminate! Soldering is tricky but the supplier sells zinc solder

⇦ on

eBay or

Amazon [affil link]

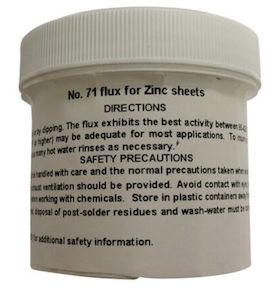

and zinc flux

⇦ on

eBay

or

Amazon [affil link]

. You will need to use a really big soldering iron! Use a sander to grind the welds, to remove the mill oxide and to achieve the level of finish you want.

Because Zinc is a reactive metal it cannot be permanently painted, (except maybe with epoxy), but after you sand it, it will take clear Krylon, for example. Coatings will not work in a wet area. Clear wax is OK but must be laboriously reapplied periodically. Zinc will be very affected by kitchen liquids including water. Discolorations can be rubbed away with a scotchbrite pad and some powdered cleanser. Because zinc sheets only come one meter wide, when making your countertop you may encounter a need for a butt joint. You can leave a hairline seam, which looks OK, or devise some kind of solder joint with a recessed backing strip. Another cool thing about zinc is that you can very easily make attractive patterns in it with a sanding block, for example if you want to make inserts for your appliance front panels, before you clear coat it.

- Chicago, Illinois

2006

Q. James,

I am planning to make my own zinc counter tops for a basement bar.

I was originally planning on using a brake to bend the ends so that the counter wraps around the edges. Are you saying that you cut a piece for the top, cemented it to the top and then trimmed it with the router. Then cut a piece for each side then did the same as the top and then soldered the seam all the way across?

- Cleveland, Ohio

2007

A. Yes, I applied the edges, routed them, then applied a piece to the top, routed the edges, and filled in the gap with solder. For simple shapes you could brake the edges like you describe, that works OK too. My island had some radiuses so braking wouldn't work. If you brake two edges 90 degrees to each other then you'll only have to solder where they fold together edge to edge.

James M [returning]- Chicago, Illinois

April 10, 2008

I had zinc countertops installed last year. I want to tell anyone considering this product it is very difficult to use. There are stains surrounding the sink area from the water that gathers while washing dishes. It scratches very easy and various foods and products leave blackish gray stains on it that will not polish out. I am very disappointed as the countertops look like I haven't wiped them. Yes, they are "old world" which is what I wanted but the look of not clean doesn't go well with a kitchen. The expense prohibits me from changing them too soon but I will in another 12 months or so.

I had zinc countertops installed last year. I want to tell anyone considering this product it is very difficult to use. There are stains surrounding the sink area from the water that gathers while washing dishes. It scratches very easy and various foods and products leave blackish gray stains on it that will not polish out. I am very disappointed as the countertops look like I haven't wiped them. Yes, they are "old world" which is what I wanted but the look of not clean doesn't go well with a kitchen. The expense prohibits me from changing them too soon but I will in another 12 months or so.

- Dallas, Texas

2007

A. This is a good point. Anyone wishing to use decorative zinc in a a home should be aware of what they're getting into. Zinc is a very active metal and will react with the environment constantly. In no time at all it will develop a tenacious patina of black or dark grayish oxides that is by no means even in appearance and shows the history of everything it came into contact with. You can try to stave off the inevitable by applying clear coats or waxes but be ready for their eventual failure. Or you can do what they do in restaurants and bars which is clean it every day (better start with some thick stock!)!

James M [returning]- Chicago, Illinois

April 10, 2008

|

|

A. I recently installed a zinc countertop in my home for my kitchen. I am very pleased with how it turned out. We had a local sheet metal shop do the bend for the corner and soldered the seams. I found this company [sorry, deleted by editor]. They were very helpful with my questions and purchasing the zinc from. They are the only ones I found that you can order right on website. I had the metal shipped directly to my sheet metal guy. I strongly recommend them for a source to get zinc sheets and the best prices even with shipping them. Dana Potter- new York, new York Ed. note: We appreciate your helpfulness, Dana, and are glad you're happy! But with the anonymity of internet forums, testimonials are of little value because shills post with fictitious names, and then claim greater satisfaction with another company (their own) than whatever one you mention :-) Also, we can't print balancing dis-recommendations because lawyers for the companies claim it is 'brand assassination' by a competitor when we can't prove a poster doesn't have a vested interest. We've already had 3 such cease-&-desist letters and had to remove stuff :-( Suppliers are welcome to do clearly labeled paid advertising here or anywhere. Suppliers can also be found on Google or Bing. This forum is for camaraderie & technical discussions, not sourcing ( huh? why?), and the spam isn't manageable; sorry :-( But some suppliers of zinc sheet who posters have mentioned, and which we will neither recommend nor dis-recommend are Belmont Metals, Brooks Custom, Columbia Metal Products, MetalTech USA, Mio Metals, Rapid Materials/Umicore, and Rotometals. |

Q. I am a do-it-yourself homeowner interested in a zinc countertop. Your site has some really good information on this topic. There is a local roofing company who has zinc sheets (28"x120") for a very reasonable price. They are .020 thick. I am covering my existing laminated countertop with zinc. Will this thickness be ample? I am not doing any welding (as I don't know how)!

Thanks very much.

hobbyist - Louisville, Kentucky

July 17, 2008

Ed. note: Readers should be cautious with the term 'zinc sheets'. Sheets of solid zinc are one thing, galvanized (zinc coated) steel sheets are something very different, but a roofing supplier might well call galvanized steel sheets 'zinc sheets'.

![]() I just had Zinc countertops installed today and they are wonderful. I purchased the zinc a few years ago with this in mind and found a sheet metal company that makes stainless countertops to fit them for me. I also bought the sheets that look like pressed ceiling tins to use for the backsplash.

I just had Zinc countertops installed today and they are wonderful. I purchased the zinc a few years ago with this in mind and found a sheet metal company that makes stainless countertops to fit them for me. I also bought the sheets that look like pressed ceiling tins to use for the backsplash.

The zinc was around $60.00, and the backsplash was about the same. I don't know what the cost for installing is yet, they are billing me.

Has anyone heard of using zinc for a shower surround? I am looking for a thrifty way to make a new surround and I think I would like the ping noise the water would make. Please advise if anyone has any ideas on this.

Thanks, Andi

home owner - Des Moines, Iowa

September 25, 2008

A. Hi, Andi. Please search the site and you will find other threads like thread 13388 about zinc for shower surrounds. Zinc must freely "breathe" lots of carbon dioxide to resist white corrosion in a wet environment so it may not be a good idea.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

A. This is for Andi in Des Moines. I went on the May house tour in Dubuque, Iowa a couple of years ago and one of the houses was a mine foreman's house with addition. Fantastic job in keeping to the spirit of the original. Used concrete countertops, etc., but the master shower was concrete bottom sloped to the drain, no lip that way, and was made out of corrugated metal on the top and sides above a 2 or 3 inch lip around the other 3 sides. it fit into a sloped ceiling and looked fantastic. The architect did the labor as he was just out of school and friends with the owners. He said that he used a couple of coats of a really good auto wax about twice a year to keep the shower from rusting and with the wax being a really good brand that you just sprayed it down with the shower head after using it. No chemicals to cut the wax finish. It had been in for a couple of years and hadn't started rusting as yet with 2 people using it every day. Hope this helps you.

Lois Gross- Clinton, Missouri

December 6, 2008

Q. First of all Ted, I am sorry to hear that your house has flooded and my heart goes out to all of you that live on/by the Jersey shore. I grew up in Marlboro and a piece of my heart is still there.

We had a zinc countertop installed 4 years ago, and I love the look. My wife did a great job selecting this material. The base for the hand held sprayer came off the countertop and I was wondering what I could use to glue it back to the counter?

Thank you

- Northbrook, Illinois USA

November 7, 2012

Thanks Stuart. I don't really know what adhesive is best, but I don't have any reason to suspect that an epoxy like JB Weld ⇦ on eBay or Amazon [affil link] wouldn't work fine. That stuff has amazed me more than once. Good luck.

Regards,

Ted Mooney, P.E.

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Ted can be retained for immediate

answers or long term project help

Q. A client of mine has allowed lemon juice to bleach a new zinc table top. It is splotchy, and she wants the marks removed. This is outside my comfort zone, so HELP please!

George JuddAntique Restoration - Salisbury Wiltshire U.K.

September 21, 2014

Q. I have recently moved from our 175 year old home where I had Vermont marble counter put in a few years ago. I went through a period of hysterics when anything spilled on them - but I grew to absolutely love the marble and now in my condo thinking of redoing the kitchen. I have been thinking of zinc and wonder where I can go to look at it. I am about and hour from NYC.

I have no idea of the cost and would love to hear from someone who just loves the look and feel of zinc.

- Millbrook, New York USA

January 10, 2016

Q, A, or Comment on THIS thread -or- Start a NEW Thread