Metal finishing Q&As since 1989

-----

Fabrication & finishing of hypodermic needles & cannulas

Q. Hello -

We have a component in our medical device (under development) that is similar to a bevel tip needle (20 gage thin walled SS tubing). As the component design is custom and requires some secondary operations (bending etc.), we are building the prototypes by grinding the tip on standard thin walled tubing. Visually, they are similar to the standard off-the-shelf needle tips but it appears that we have burrs and other irregularities (not visible to naked eye) that is leading to a higher penetration forces in the target tissue.

None of us in our team have background with needles and we are wondering what type of electropolishing would be appropriate without losing any tip sharpness. It seems that this is likely a routine and well-established process and my apologies for asking a rather basic question here. I truly appreciate your help.

- Minneapolis Minnesota

January 4, 2023

A. There are some tricky ways to electropolish tips without loosing sharpness. I cannot say for sure if it works until we test your samples. My experience tells me that acid-free electrolyte might work.

Anna Berkovich

Russamer Lab

Pittsburgh, Pennsylvania

A. J,

I'm stepping a little bit outside my wheelhouse here, but I have my doubts that electropolishing will be a sufficient deburring process for you. You may just end up with polished burrs. Of course you'll have to try it out to see. A more traditional mechanical deburring process like tumbling or vibratory bowls might be the better option in the end, though. Either way, most likely the easier path will be to do your deburring before, rather than after, sharpening the tip.

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

January 9, 2023

Older topics: Read all or Jump to

• Bore Improvement

• End Closing

• Chemical Polishing

• Electropolishing

• Applying Gauge Lines

• Siliconisation

Student question: How do they get the hole in?

Q. Our question, How do manufacturers make the tiny hole through a hypodermic needle? We have asked several people we thought might know, pharmacists, doctors, etc. and so far no one can explain it. It started out as a simple question but now we are on a quest to find the answer. We are junior high science students.

Carol C [student's last name deleted for privacy]- Guymon, Oklahoma

2001

A. Hi Carol,

I believe that the only way to do this is to firstly make a much larger tube (using stainless for needles) and to FILL that tube with a material that can be easily, so-to-speak, removed. I think it was copper.

Why? Because if you cold extrude or cold size, and pass unfilled tubing through a range of ever decreasing dies to get very, very small tube diameters, you'll get ovality if not complete distortion and flattening.

In the rolling mill industry the super fine rolling mill design is called a Zenzimir (or a word sounding very much like that) but I don't think that by itself it can make hypo needles. But the initial tubing? Most probably.

The next problem is to try to remove the 'filler' material. Thousands and thousands of needles are placed in a nitric acid tank ... and not days, not weeks BUT months later the acid eventually leaches out all the copper. Presto, super fine holes in a super thin material. Ergo, you have your fine needle. OK? Aren't you lucky you are growing up in a world where, compared to Ye Olden Days, injections used to hurt!

Now you can go tell all your pharmacists and doctors HOW TO DO IT!

Freeman Newton [deceased]

R.I.P. old friend (It is our sad duty to

advise that Freeman passed away 4/21/12)

A. Having been in the medical needle business for over 20 years, I can tell you how this is done. A flat, ( I believe it is about 1 1/2" in width) strip of 304 stainless steel is roll formed and welded at the joint into a tube. The tube is then annealed and drawn down through a series of dies with a floating mandrel on the inside of the tube that keeps the I.D. consistent. Where ever needed, additional annealing is performed to keep the desired physical properties and draw characteristics of the stainless steel. If you look at a relatively large needle under magnification, you can find the weld line! This is the beginning for every needle manufactured even down to a 30 gage.

For more information you can contact the tubing manufacturer K-Tube Corporation in San Diego California. I hope this helps!

Best regards,

- Keene, NH, US

2003

![]() I would like to thank Frank for his accurate response to this posting. He is correct. These days, tubing is made on a tube mill by first forming then welding, either with a laser or TIG welding operation.

I would like to thank Frank for his accurate response to this posting. He is correct. These days, tubing is made on a tube mill by first forming then welding, either with a laser or TIG welding operation.

miniature stainless tubing - Poway, California, USA

2003

Multiple threads merged: please forgive chronology errors :-)

Bore Improvement in Long Hypodermic Needle Tubing

Q. Information requested on a method to improve the Bore in Hypodermic Needle Tubing 316 Stainless Steel of 1 meter length. ID 2.5mm (0.1"). WT 0.4mm.(0.016"). The bore is quite good on commercial hypo tube, however there are small rings and diameter variances produced in the drawing process. These need to be reduced to give a consistent round bore over the full tube length. The ID surface is also not very polished, compared to the outside. This needs improving to say 0.1 Ra. The actual finished diameter is not critical, it is the ID consistency and ID polish that is important. Straightness of the tube is not important Batches of 500x1 meters to be finished. Must be 1 meter minimum length. Other tubes in diameter range of 2 to 5mm ID also to be finished.

Peter Holdswoth- Gisborne, NewZealand

2001

A. You can use an electropolishing method, to clean ID of 304 stainless steel tubings. As we manufacture reusable hypodermic needles, we are following this method to clear ID of 304 s.s. tubes, and it gives satisfactory results. Moreover, ultrasonic cleaning method is also very much useful (media should be T.C.)

Mr. Jhaveri- JAMNAGAR, GUJARAT STATE, INDIA

Multiple threads merged: please forgive chronology errors :-)

End Closing

Q. Dear Sir,

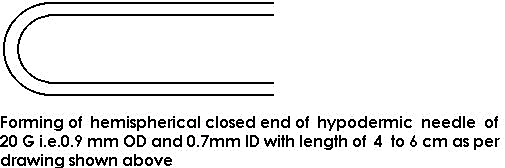

We are interested in forming hemispherical closed end of hypodermic needle of 20 G i.e.0.9 mm OD and 0.7mm ID.

Material Type: Stainless Steel 304, 316 or 316L

Condition : Hard and preferably should be maintained

We are attaching drawings for your reference and suggestions to us.

Please reply by your earliest.

Thanking you,

Amrut Patel- Ahmedabad, India

2002

A. Amrut,

My first suggestion would be for you to go to a local 'pipe bending Company' for some advice ... although you can be l00% sure they would have never 'bent' something so small !

Bend radius! If you cold bend your needle, either it will break or it will flatten out. The absolute min. bend radius I would consider is 6 x diameter and that's using heat to form over(i.e., around) a mandrel. Maybe start off @ 8. The larger the radius, the better

(quality) the bend.

You state that the needle's end(s)are closed. In the metal pipe bending field in order to make perfect bends, they use a 'rosin' which is heated up to well under 100 °C but, upon cooling, becomes solid. This allows for excellent bends to be made in certain materials (copper) without heat.

Somehow that sure doesn't seem feasible for you. Summary... use heat (to red hot), use a large bend radius.... and cross your fingers!

Freeman Newton [deceased]

R.I.P. old friend (It is our sad duty to

advise that Freeman passed away 4/21/12)

A. I understand your drawing to show a section of the tube, with the end closed. I see nothing in your query or sketch about bending. I think Freeman has mis-read the situation.

Assuming you need a gas/liquid-tight closure, you'll probably be able to get it done by a company that manufactures thermocouples. The usual way of closing the end of the metal sheath of mineral-insulated thermocouples is by TIG welding. This is on tubing down to a couple of mm inside diameter. It's a small TIG-welding setup! For a tube as small diameter as yours, you wouldn't need any filler metal.

Probably, electron-beam welding would also do the job OK, but might be a problem accommodating the tube in the vacuum chamber. I'd go for the TIG.

Bill Reynolds [deceased]

consultant metallurgist - Ballarat, Victoria, Australia

We sadly relate the news that Bill passed away on Jan. 29, 2010.

Multiple threads merged: please forgive chronology errors :-)

Chemical polishing of ss needles

Q. Please let us know about the chemicals used for chemical polishing of SS hypodermic needles Grade AISI- 304.

Sanjeev Paul- Gurgaon, Haryana, India

2003

A. Sanjeev!

I would have thought that the 'polishing', as you call it, would really be due to the extruding process using the multi roller Zendsimir (Zensimere? ... spelling?) used for ultra pressure and ultra small diameters.

I've seen hypodermic needles by the mega thousands all resting in a nice nitric solution to leach out the copper cores ... a very slow process indeed!

Freeman Newton [deceased]

R.I.P. old friend (It is our sad duty to

advise that Freeman passed away 4/21/12)

Multiple threads merged: please forgive chronology errors :-)

Electropolishing of needle/cannulae / Non uniform results

Q. With surgical devices, what is a typical Ra finish that we would be expected to achieve on such a device?

Michael HealyMedical Equipment - Automation Engineer - Cambridge, Ontario, Canada

2003

A. Point Technology reports super polishing of W (tungsten) needles with a Ra below 10 nm.

Peter BRADLEYTechnology analysts - Switzerland

Q. We are doing electropolishing of medical needles being used for I.V.Cannulae. The basic purpose of electropolishing is to remove the grinding burrs(burrs can not be seen by eye) from the needles/cannulaes. We are making a bunch (30mm * 30mm) of needles and putting it in the phosphoric acid bath (85% concentrated). The tip of the needles is pointing upwards. Needles are made anode. On the top of it we are placing a stainless steel cathode(plate shape) at a distance of 50mm from the top of the needles. The plate/cathode is also fully immersed in bath. We are getting variations in results in the needle kept in the centre of bunch vs the needle at the edge of the bunch. The voltage is 5v and the current drawn is 10 amp. Can any one advise the solution to have the uniform results all over.

PRADEEP JAINmedical equipment engineer - Gurgaon, Haryana, INDIA

2004

A. I assume you are holding your parts on a fixture in a straight line. If this is the case the peripheral parts on your jig will always pull more current than the center parts. Thus your edge parts are possibly over polishing or rounded.

There are methods of improving the capability of your process i.e. equal current distribution:

1) round Jig and round cathode

2) individual rectifier to each part

3) curved cathode using a straight jig

I would be interested to see if there are other solutions to providing an equal current distribution across all parts.

- Ireland

A. Placing cathode above the needle end will cause the high current density on the end of the needle, thus making round the tip.

In order to reduce CD, place the needle inside the rounded cathode, tip of the needle must be 10-15 mm above the cathode.

The proper cathode configuration will improve the results, however in order to guarantee sharp deburred needle tip, you need to select proper electrolyte and polishing regimes.

adv. We see good results in our Universal electrolyte or in our Ultrapolishing electrolyte. Presently electropolishing is developed for titanium, nitinol and stainless steel I.V. needles.

Anna Berkovich

Russamer Lab

Pittsburgh, Pennsylvania

Q. Hello,

I work in a factory manufacturing surgical needles for sutures. We use SS302 and 301 in our manufacturing line. One of the finishing steps is electropolishing process. The goal of implementing the EP line is to deburr, brighten, passivate and finally to improve the performance (lower penetration force). Our products on which we perform EP are bent, can either have round shaped body with taper point, or triangular shaped body with triangular cutting edge tip.

My question is regarding how EP works on parts with complex shape and how to master them. I understand that EP removes the inconsistencies on the surface by measuring the difference of current density (higher current density on surface peaks results to higher rate of removal).

Our workpieces don't have the most complex shape, but we still have difficulty in understanding how electropolishing attacks the tip of the needles. For example, we notice that when there is burr on the pointy tip, EP could not remove it. If there is burr on the cutting edges, EP could remove it to an extent. Another thing that we notice as well is the tip becomes much more fragile after EP. It is as if the tip becomes thinner but the extreme point stays the same. Is EP highly dependent on the positioning of the workpiece? Our workpiece is placed flat on the anode, so the tip is pointing perpendicularly towards the cathode and the anode.

I tried to be as detailed as I can without the message being too long, so feel free to ask me if I need to clarify anything.

- Samut Prakan, Thailand

April 18, 2022

Q. Dear sir,

Have you found your fault? Because I am doing the same test on medical needles and I am very interested to hear what have you done!

I myself thought that the current density was very high. CD should be almost between 2-5 amp.

Do you find any ASTM standard for medical needle electropolishing?

- Tehran, Iran

February 22, 2012

Q. Hi Mr Aimran Nadzmi, I have the same problem, Have you found the resolution for it?

Kinh Dinh- Vietnam-Hanoi

September 5, 2022

A. Hi Aimran; Hi Roozbeh; Hi Kinh. Electropolishing smooths parts and passivates them. It can brighten them if they are dull. However, 'deburring' is a different operation than electropolishing as far as I know (but I have no hypodermic needle experience).

Secondly, a problem to bear in mind is that electropolishing doesn't "know" that you consider "this lump" a design feature but "that lump" a burr. We can't expect the electropolishing solution to know to not dissolve this lump but to continue to dissolve that lump :-)

It might be that mechanical finishing (tumbling, vibratory finishing, etc.) is better suited to your particular burrs and should be used before electropolishing. My experience is limited, but I not aware of electropolishing being used to sharpen a point, and it sounds unlikely to me.

Luck & Regards,

Ted Mooney, P.E. RET

Striving to live Aloha

finishing.com - Pine Beach, New Jersey

Q. Aimran, can you share the photo of jigs you use to hold your needles.

Bendy Mark- Germany

November 17, 2022

Ed. note: Welcome! and please feel free to read everything here anonymously; we have a great search engine for that ...

But this isn't a consulting service -- it's a community with a 30-year legacy of aloha incompatible with anonymity; please don't post without your real name :-)

Q. We perform electropolishing on small bent suture needles used in surgeries and operations. Our bath is around 40% H3PO4 and 40% H2SO4.

We have problem concerning the quality of the tip of the needles that it becomes too fragile after EP.

Our process team from our mother company insists that the diameter loss be between 6 to 12 microns, to prove that the needles have gone through EP.

Conforming to these instructions, the tips are still as fragile at the low extreme (6 microns of diameter loss) as it is at normal setting (around 9 to 10 microns of diameter loss). By fragile, I mean that the tip easily become crooked during manipulation of the needles after EP. It seemed as if more material is dissolved around the tip rather than the tip itself (difficult to verify this as we are dealing with really small parts).

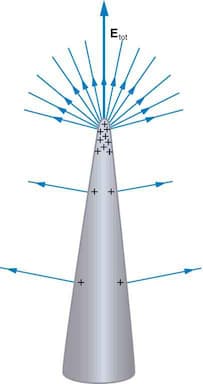

Therefore, I was wondering how does EP attack sharply curved points. I read somewhere that electrical charges tend to accumulate on sharply curved areas. How does this affect the EP? Does it dissolve the extreme tip at the same rate as the other parts of the surface?

Do you think by changing positioning of the needle we can have different effects? I.e. having the needle pointing towards the cathode.

Or do you think it correlates with the type of bath that we use?

Thank you in advance for your support.

- Samut Prakan, Thailand

May 3, 2022

A. Samut,

It all has to do with how electric current flows off the microscopic features of the piece while immersed in an electrolyte bath. You are correct in that the current flows more off the "peaks", but the tricky part is learning how that works when you have a macroscopic feature like the needle tip. As you said, the tip gets thinner rather than being solely dissolved down from the point.

I'm not well versed in this, other than to know it's very complicated. In many respects, electropolishing is as much an art as a science, being able to craft the electrode arrangement and such in order to control current density as required for the shape of the piece.

Ray Kremer

Stellar Solutions, Inc.

McHenry, Illinois

![]() Ray,

Ray,

Thank you for your input. It is interesting that you talk about electrode arrangement. I just noticed an error in my previous question. Actually, the tip of the needle is parallel to the electrodes.

Q. In theory, if I put multiple cathodes around the workpiece it could work no? Or an electrode with a concave shape that covers until the front of the tip.

We will try to do some tests of having the needles pointing towards the cathode to see the effect.

Besides that, do you know about the accumulation of charges in corners or at pointy areas? (see photo)

I am having trouble understanding how this will affect EP.. Logically I thought it would help dissolution at the tip but it is not the case.

- Samut Prakan, Thailand

May 4, 2022

Multiple threads merged: please forgive chronology errors :-)

Applying gauge lines on a hypodermic needle

Q. We need to mark a stainless steel tubing with stripes for marking the distances. We want to know which method could be the best and least expensive. And with what kind of machinery is needed.

We are a hypodermic needle factory and we want to mark a tubing with an O.D of 0.0650 inches and we want to mark the tubing a distance of 1 centimeter each one the total distance of the needle is 9 cm with the first mark on the first centimeter. The width of the mark of 1 millimeters.

engineer - Mexico city, D.F., Mexico

2003

A. It depends on what surface finish you want on the markings. Maybe you cannot use paints. So, you can mask with 9 mm wide vinyl tape leaving 1 mm openings and sand blast them. Another way would be to grind them very lightly with a 1 mm thick cutting disk. If the needles are rotated, both methods will leave a circular mark. A small suitable turning device can be purchased for a few dollars.

Guillermo MarrufoMonterrey, NL, Mexico

Multiple threads merged: please forgive chronology errors :-)

Medical engineer asks about siliconisation of needles

Q. I am interested in knowing about the process of Siliconisation of stainless steel . I know that some manufacturers treat their needles with this process mainly to give it a smooth surface . Does this process improve the corrosion resistance of stainless over a needle that has been only polished . I am also interested in knowing how this process is carried out on needles .

Preethammedical equipment engineer - Nilgiris, Tamilnadu, India

2003

A. Our company has a US patent on the application of a bis-silane to stainless steel for medical devices. The silane is a silicon based chemical, not SiH4 but bis-tri-ethoxysilyl ethane that is both corrosion resistant and imparts a non-stick characteristic to the part.

Dave Fairbourn- Sandy, Utah

A. Siliconisation is required for reducing the coefficient of friction on the needle. DOW makes a solution which is used for siliconisation. SOP I do not know but one can ask Dow.

Dhiren Mehta- Mumbai, India

2004

A. Siliconisation of needles/cannulas can be done by Dow Corning's MDX4-4159, which is a 50% Medical Grade Silicone Dispersion.

Eray Berberoglu- ISTANBUL

December 20, 2011

Q, A, or Comment on THIS thread -or- Start a NEW Thread